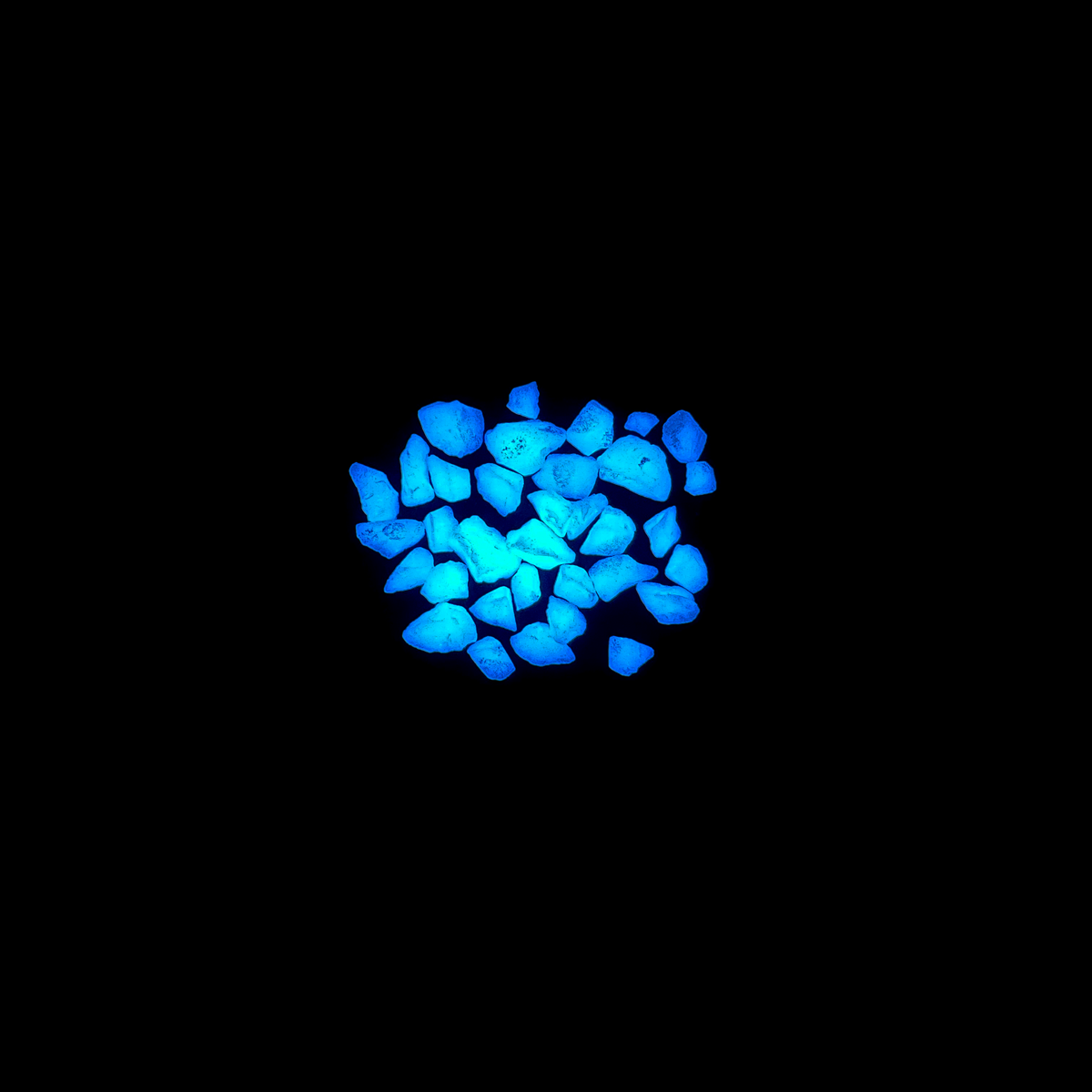

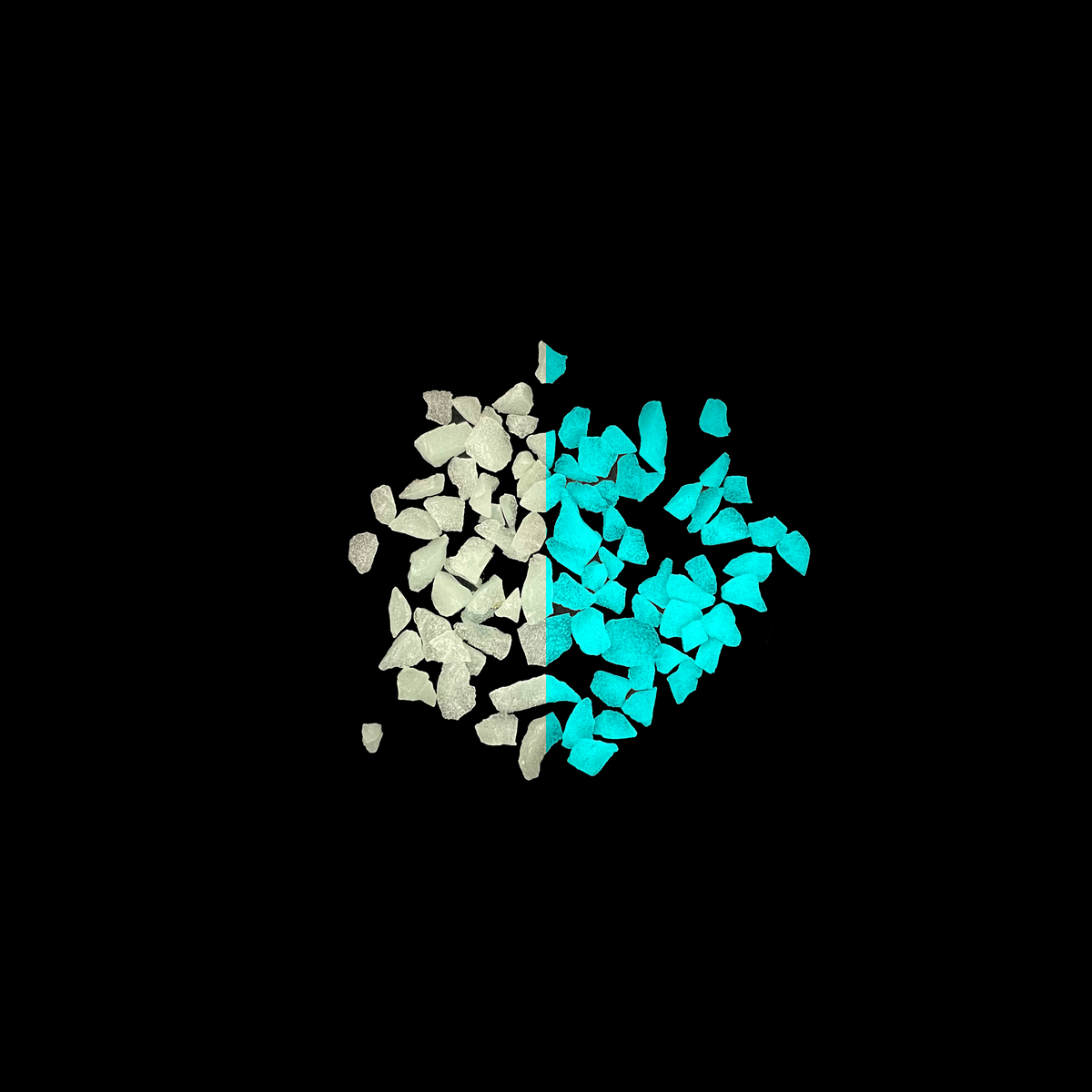

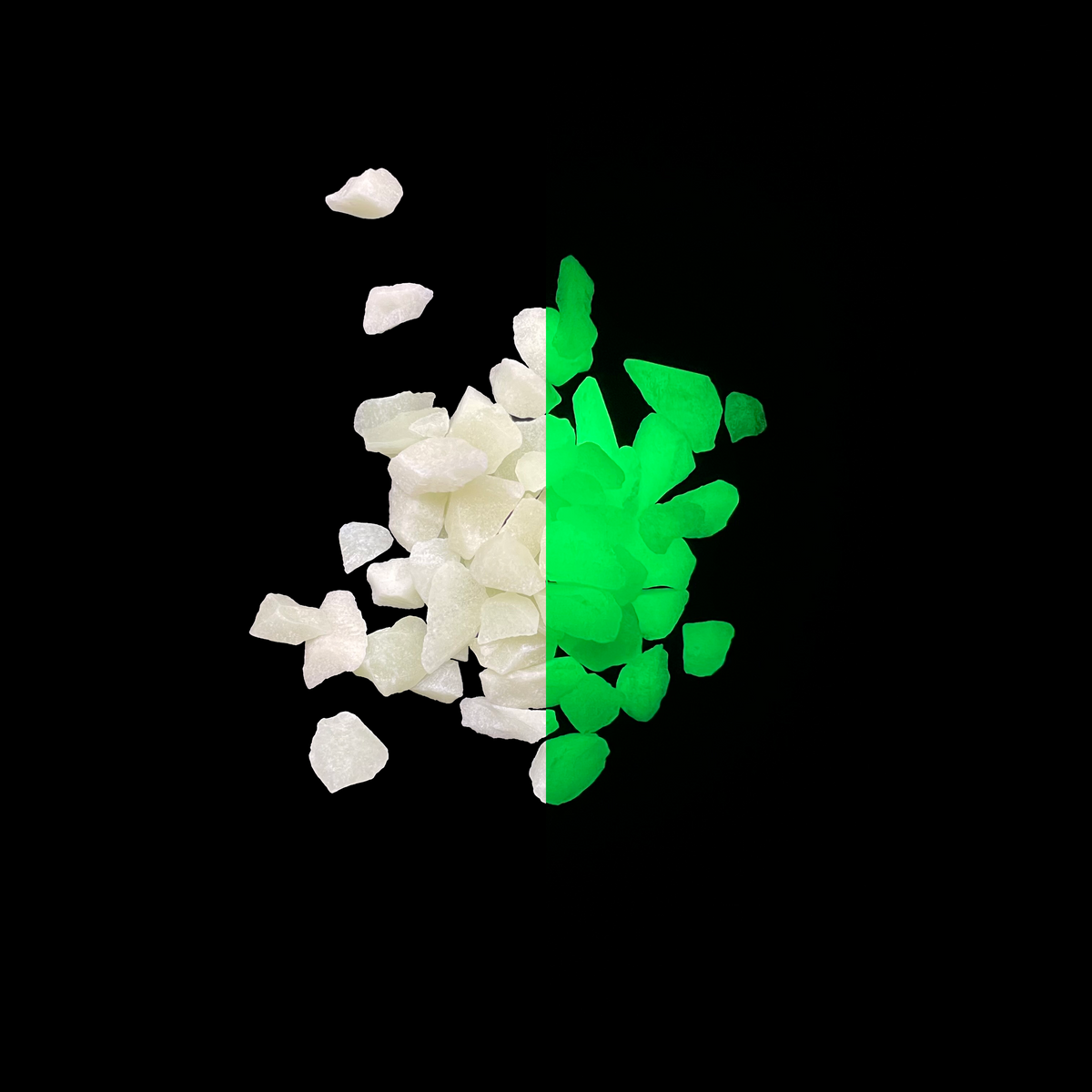

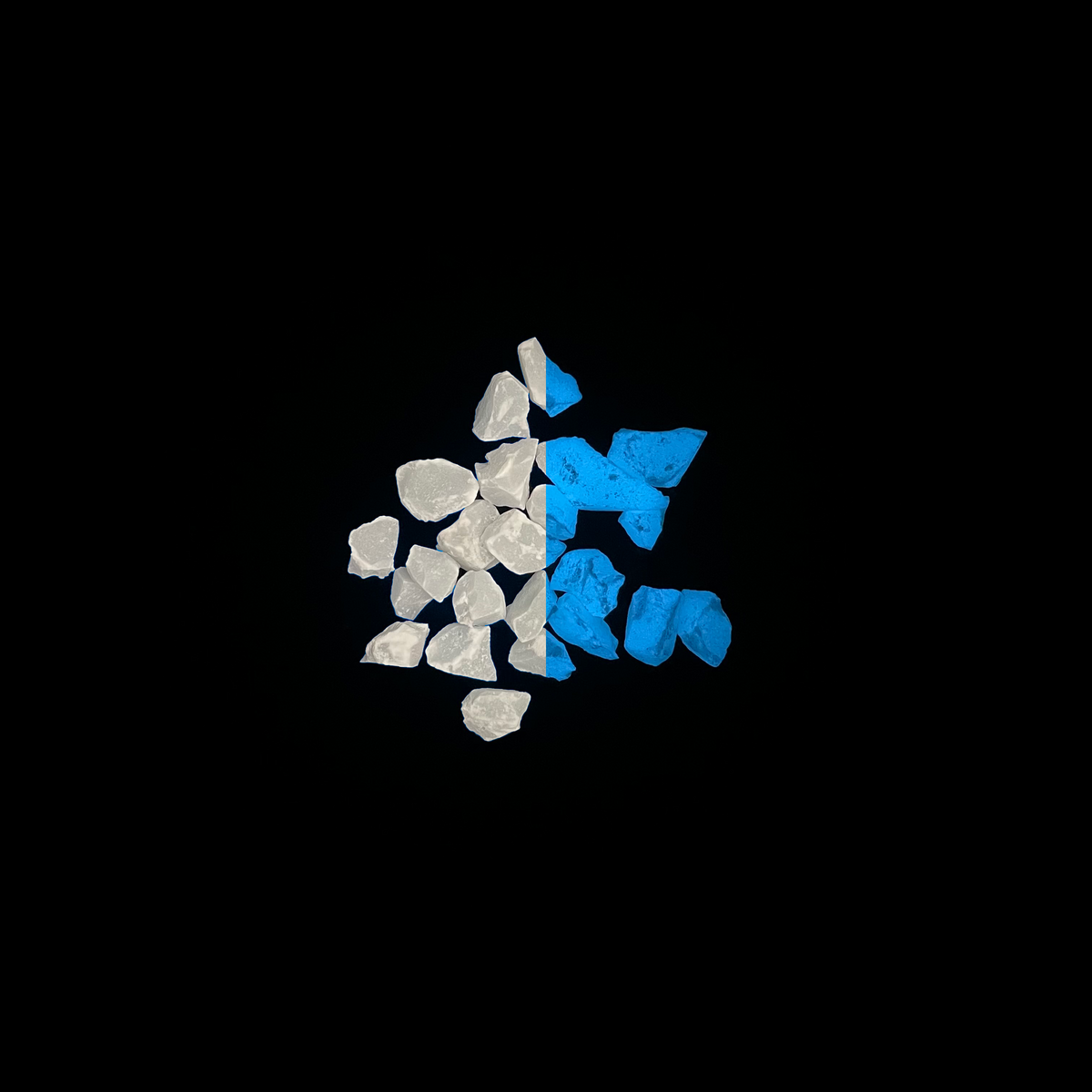

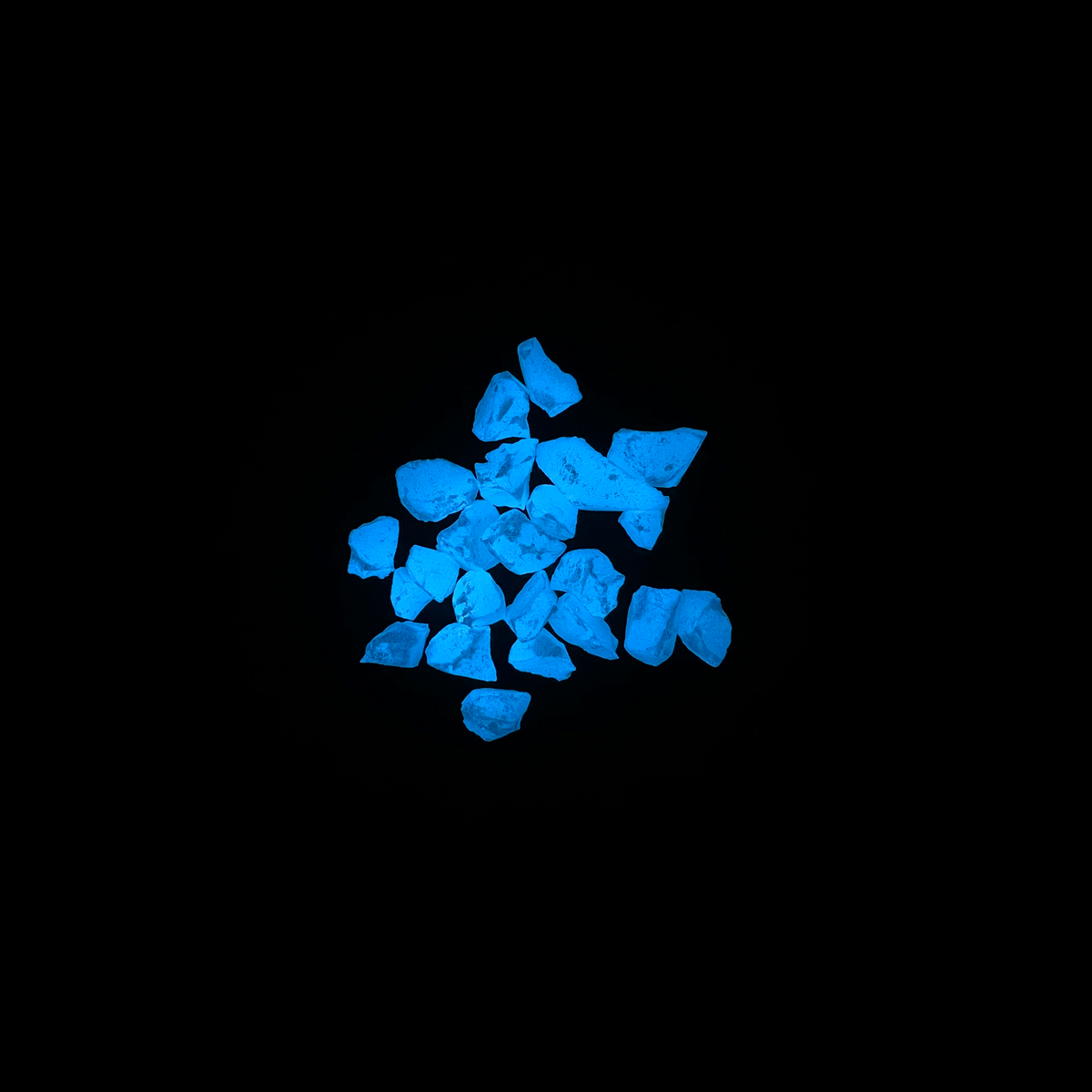

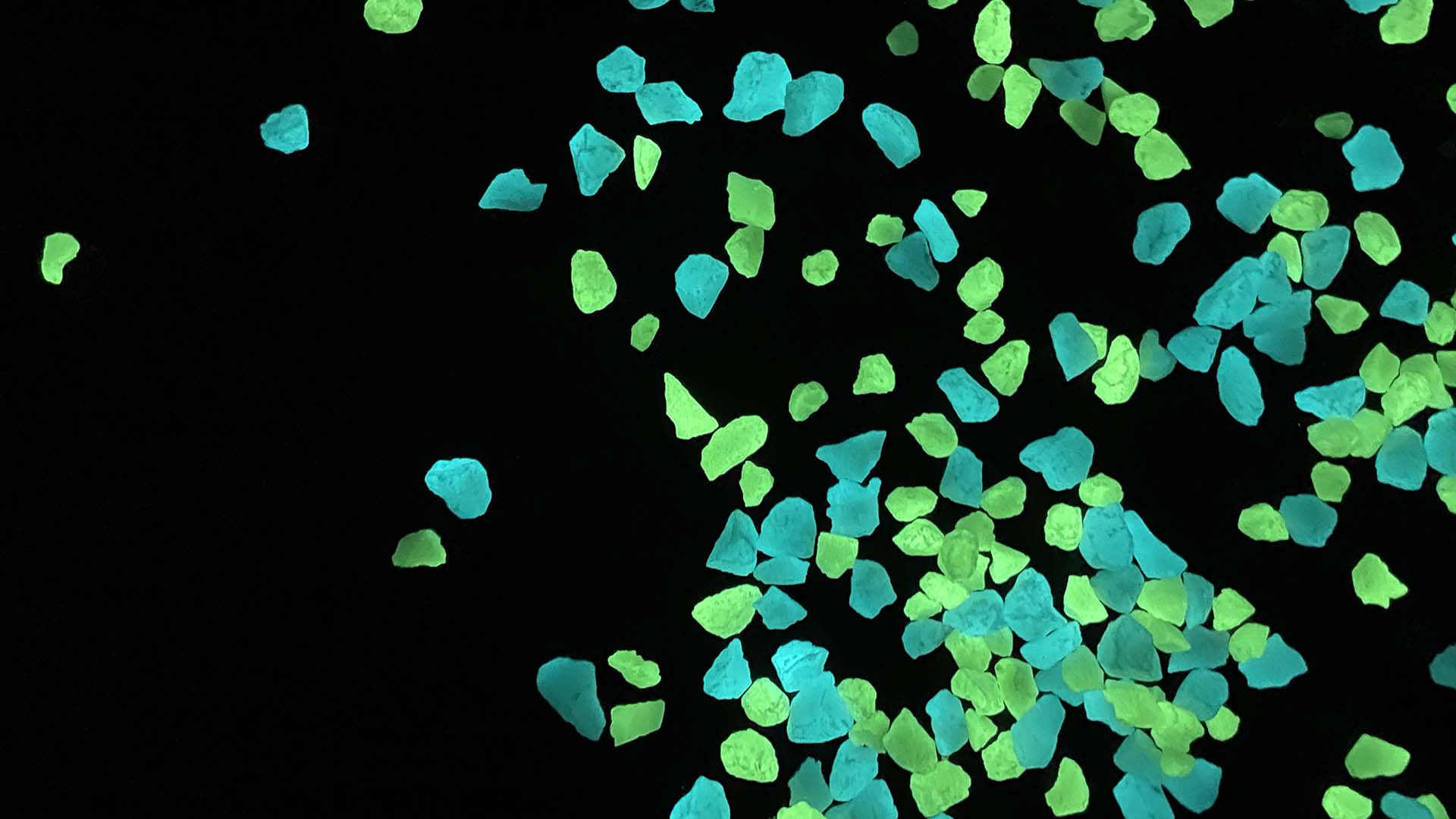

Better Than the cheap, Glass or plastic Glow Stones you find on google searches...

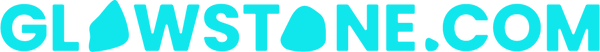

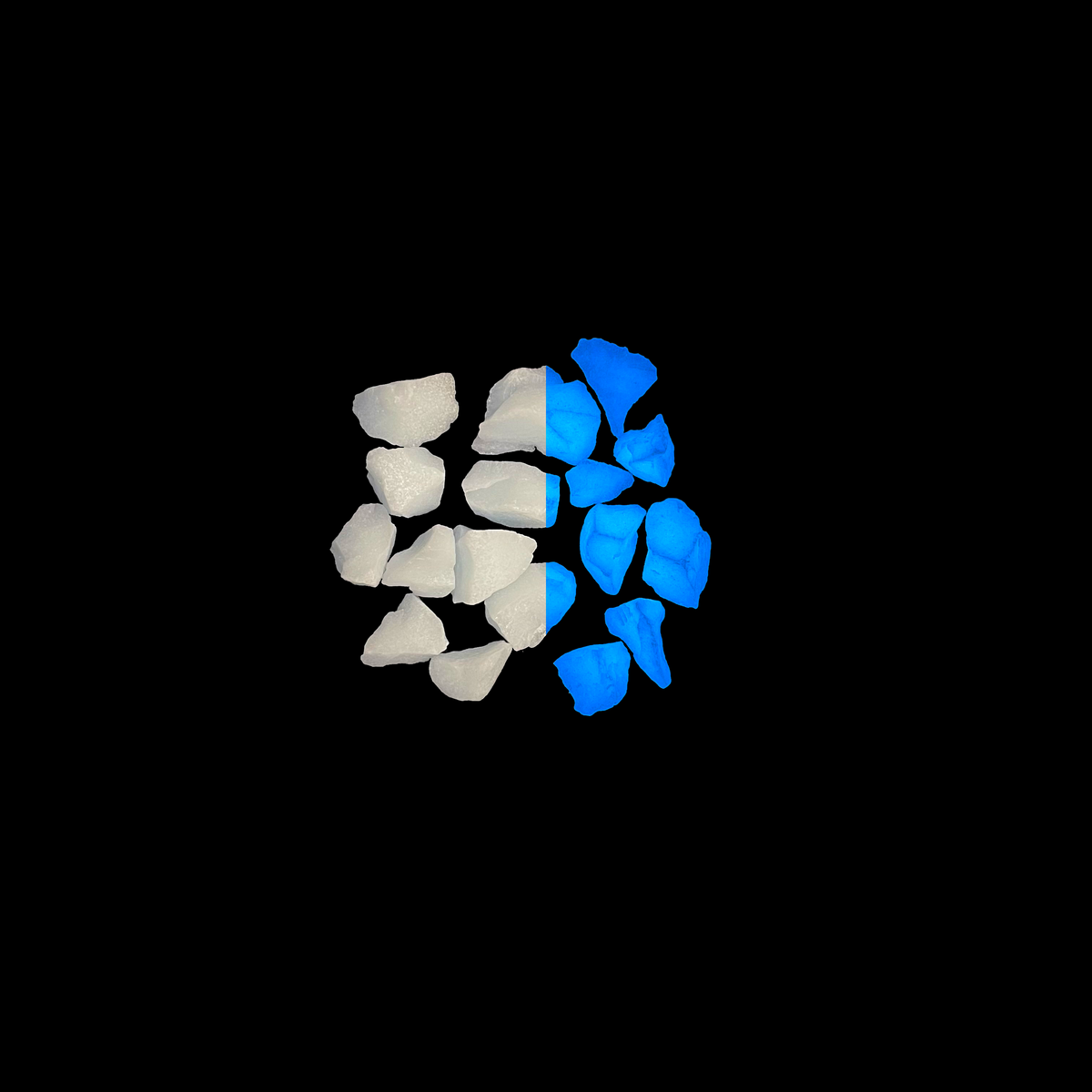

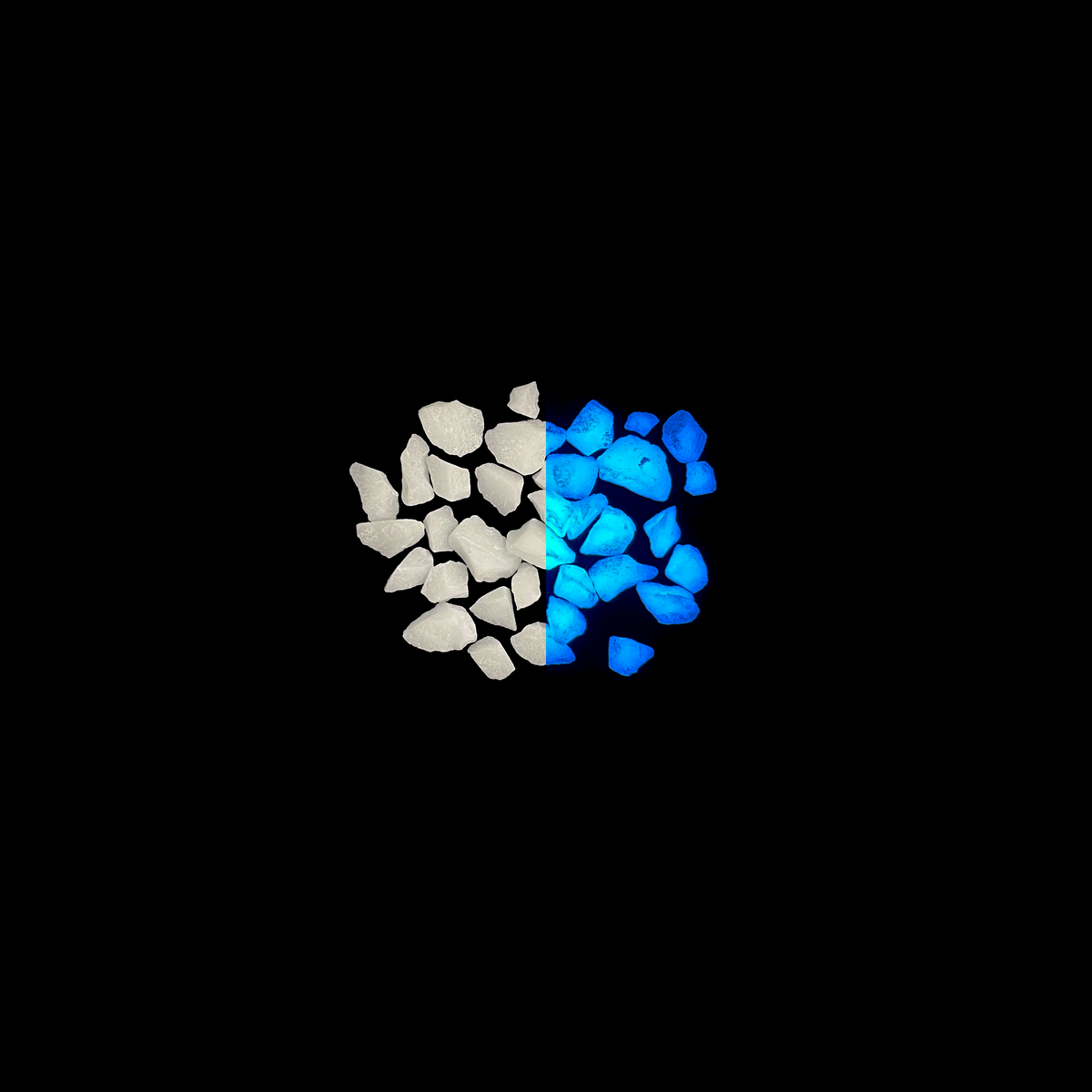

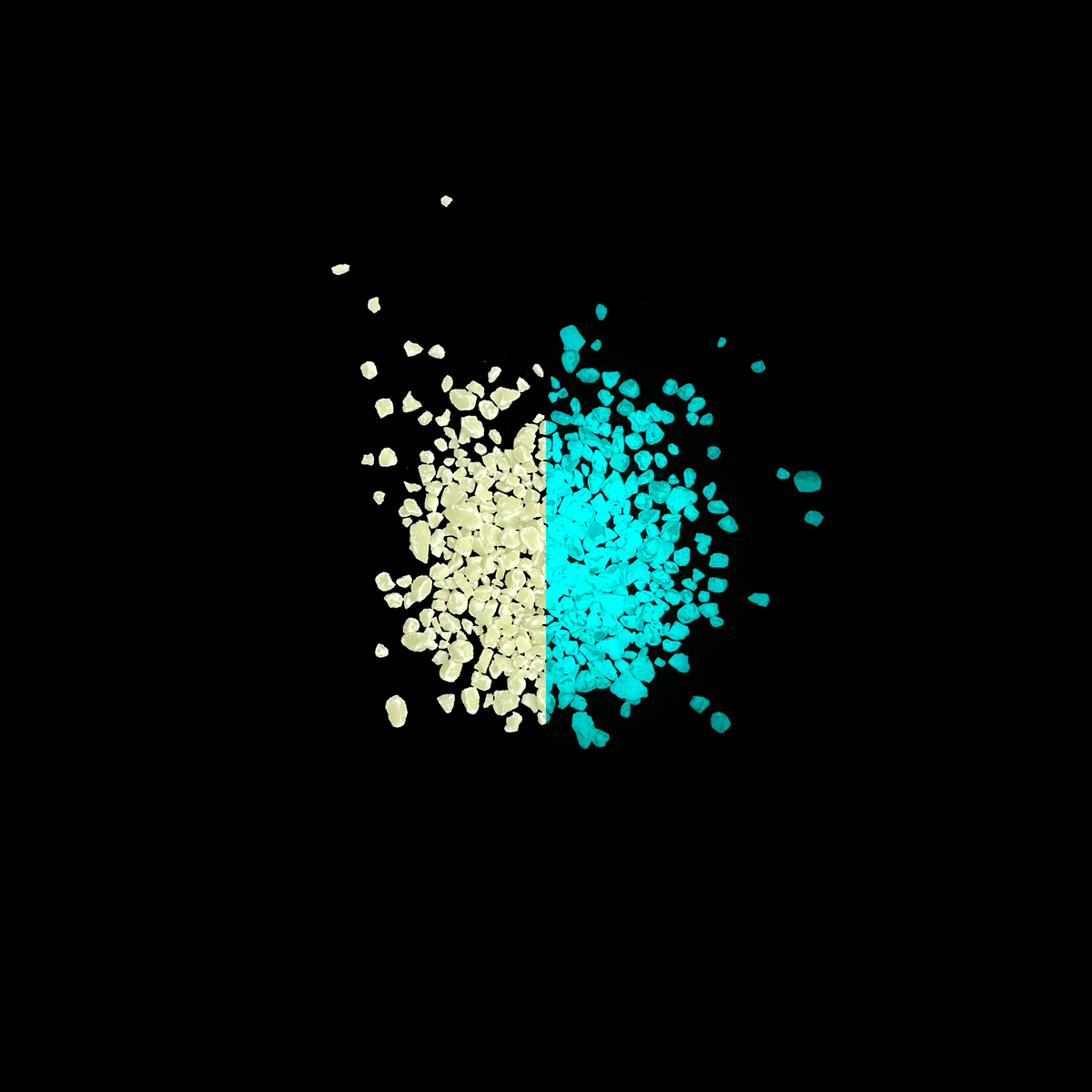

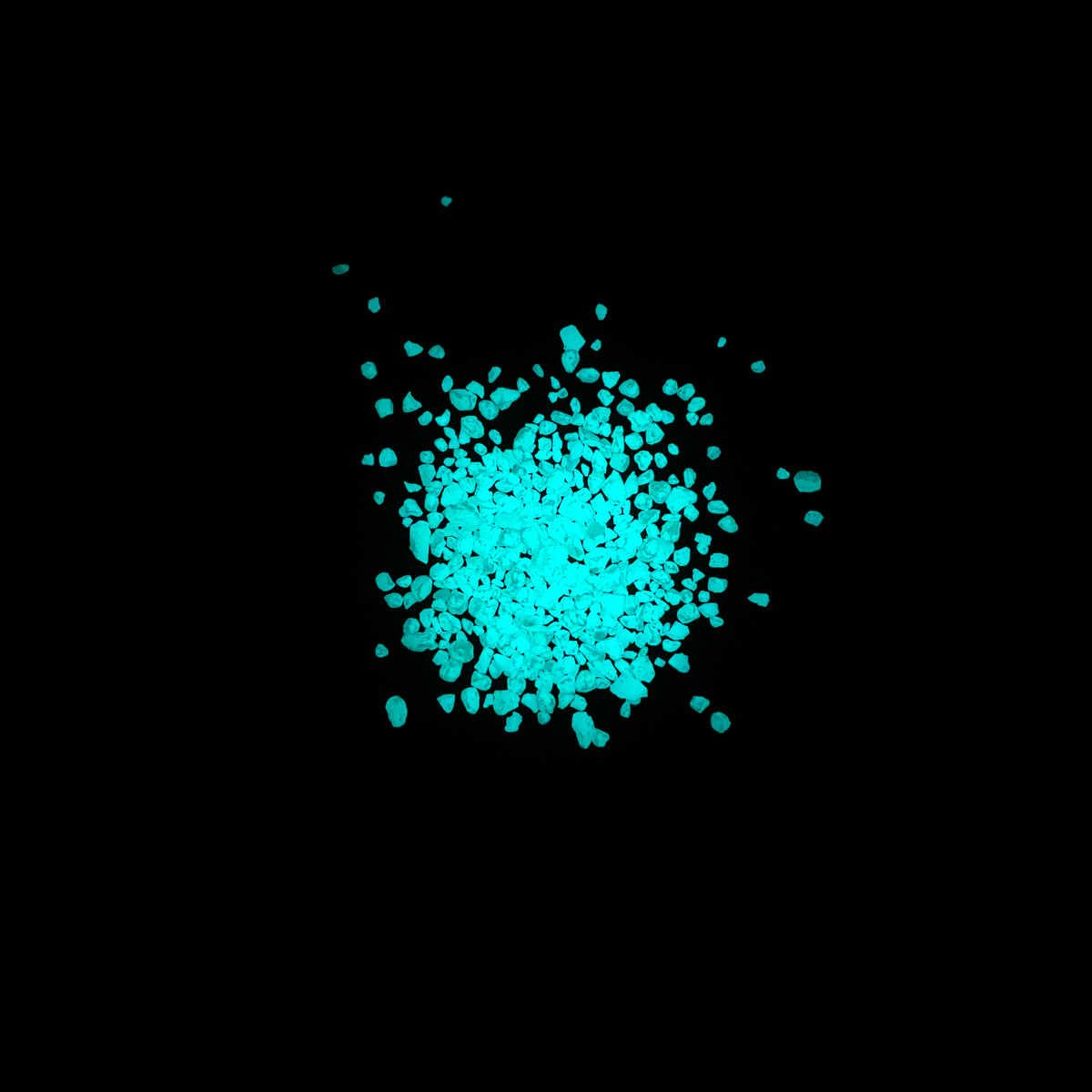

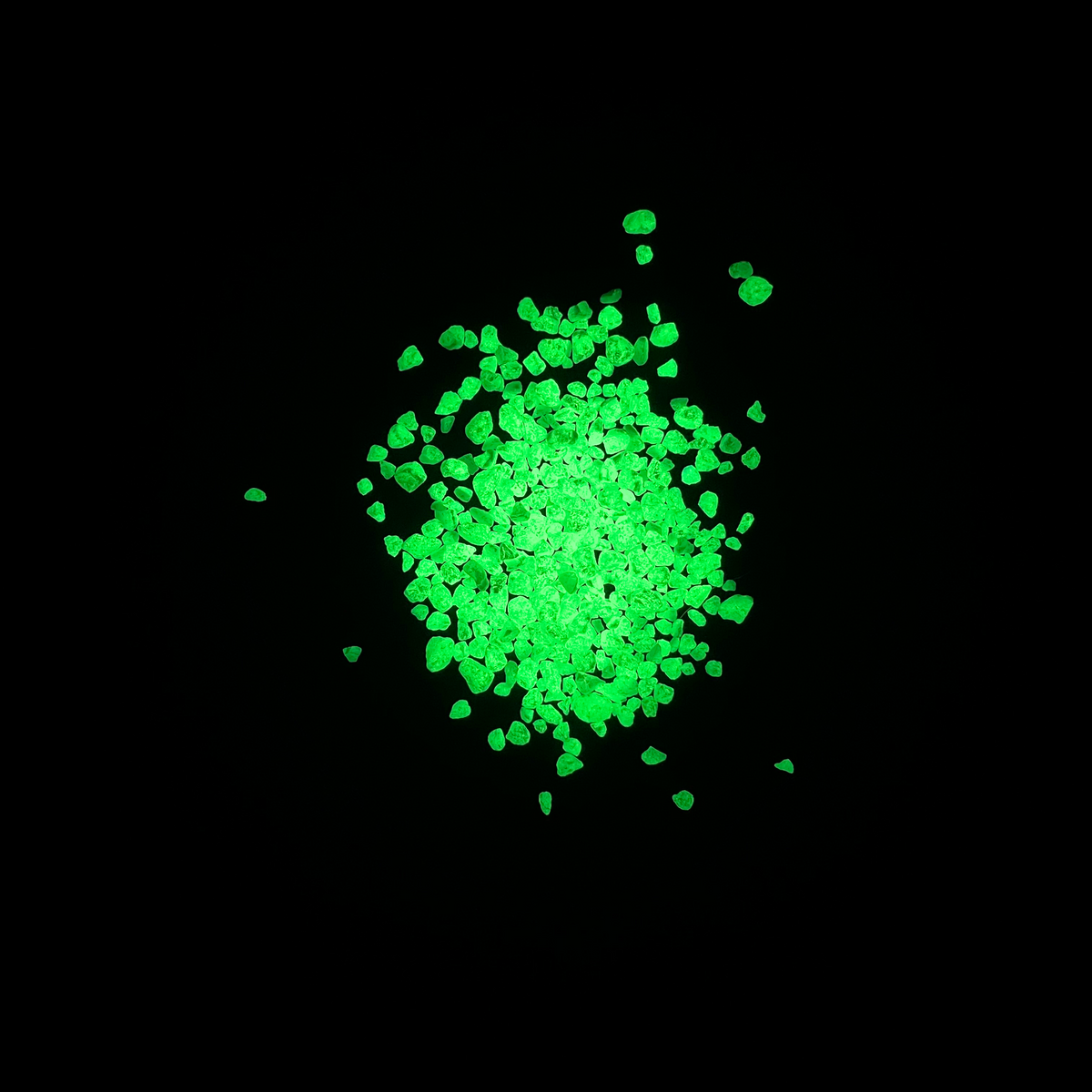

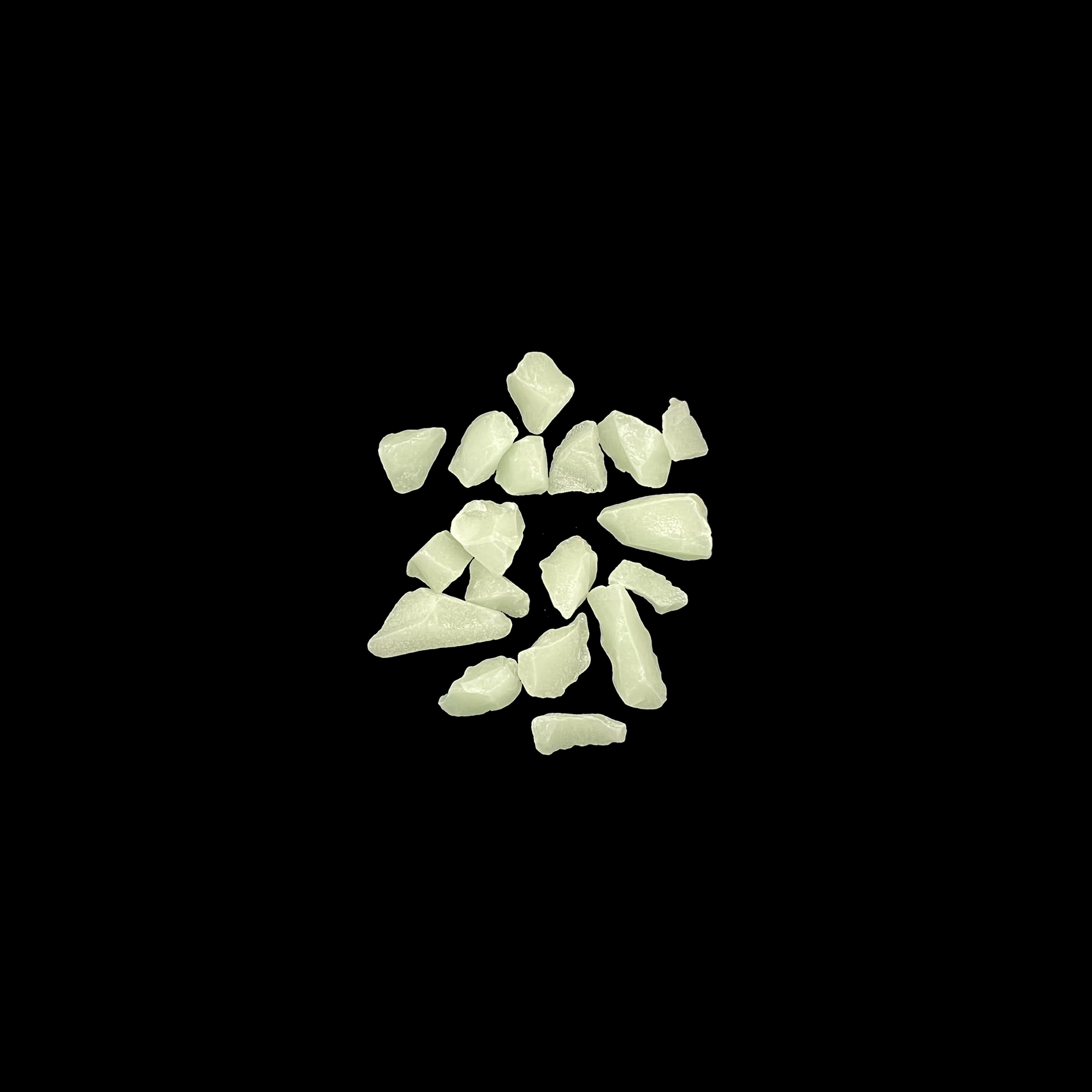

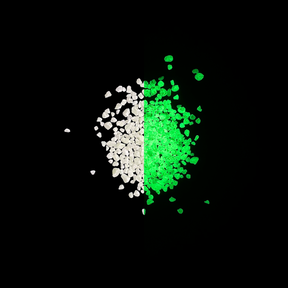

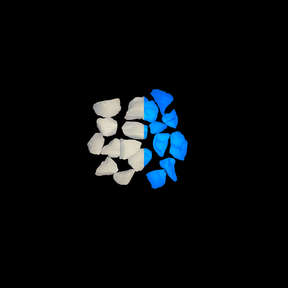

Purchase AGT™ high performance glow stone batch product at discounted prices. We know that there are many sellers of glow stones online and their products range in glow quality. Some of the cheapest glow stones glow for only 5-10 minutes while the more expensive ones glow for over 8 hours. About 3 years ago, the technicians at AGT™ Glow Labs were tasked to develop a more economically priced glow stone that exhibited better glow performance than the cheap plastic or glass chip glow stones typically found in Google searches. In the process, we developed two new types of glow stones: AGT™ STANDARD Grade and AGT™ Glow Quartz.

*Please note, these glow stones were produced in limited batch quantities so once inventories are exhausted – they're gone for good!

Featured product

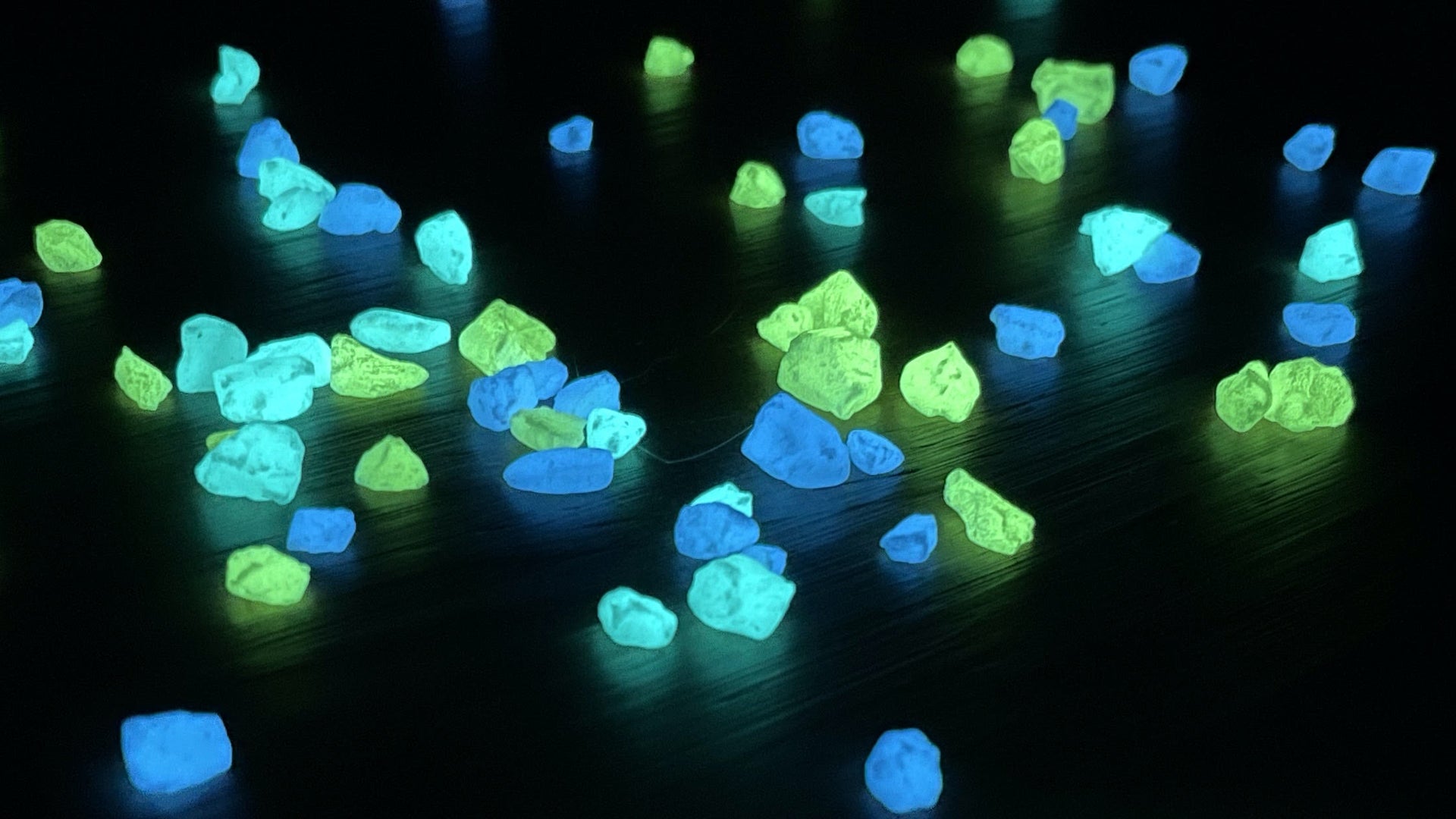

ELECTRICITY-FREE, ECO-FRIENDLY LIGHTING

Add some fun to your next project by using affordable, eco-friendly glow stones!